The flu affects most people at some point in their lives. Almost everybody experiences the flu multiple times in their lifetime.

Read MoreThere has been much discussion about silica dust in the past few years. OSHA has issued a regulation to help protect workers from overexposure to this dust. It has been largely unregulated in the past, and because of this, many workers have been faced with overexposure to silica dust. The CDC reports that an estimated 1.7 million U.S. workers are exposed to silica dust on the job.

Read MoreOperating heavy equipment or a motor vehicle is inherently a hazardous task, however, backing up creates more risk for incidents to occur. According to the National Safety Council, backing accidents cause 500 deaths and 15,000 injuries per year. All too often, unnecessary backing is responsible for injuries or property damage incidents. It is important to consider the hazards of backing and what can be done to mitigate these hazards.

Read MoreWe use batteries to power our cars, trucks, tractors, forklifts, construction equipment, and power tools. There are different types of batteries. For example, a lead-acid battery usually uses sulfuric acid to create the intended reaction. Zinc-air batteries rely on oxidizing zinc with oxygen for the reaction. Potassium hydroxide is the electrolyte in common household alkaline batteries. The most common electrolyte in lithium batteries is a lithium salt solution.

Read MoreIndividuals who come to work under the influence of drugs and alcohol are a big concern for many employers across the world. In the United States, it is estimated over 60% of employers conduct pre-employment drug screen. The cost of these tests are anywhere from $20 to $60 a piece. Since employers are willing to spend this amount of money on screening employees many find that the benefits outweigh the costs.

Read MoreEvery single year there are 735,000 Americans who suffer heart attacks according to the CDC. Out of that number, 525,000 of them are first-time heart attack victims. Heart disease and heart attacks are an unfortunate reality in our country.

Read MoreAn important but often overlooked aspect of safety is what we decide to wear each day on the job….

Read MoreSlips, trips, and falls are one of the leading causes of injuries and fatalities in the workplace. According to OSHA, slip, trip, and fall incidents cause 15% of all accidental deaths and are second only to motor vehicle incidents as a cause of fatalities on the job. These types of incidents can result in life-changing injuries to the employees who suffer them. These incidents are also very costly for businesses. HUB reports that the average slip and fall injury costs $20,000.

Read MoreHealth and safety is of primary importance when working in the field. LMK Pipe Renewal

desires that each employee be thoroughly aware of the following preventative measures: Field

workers have an exposure to polluted water and refuse by virtue of the very nature of their work

during the installation of the liners.

Read MoreThe LMK Pipe Renewal safety Committee will provide safety training of the following types.

All employees, as specified are required to receive such safety instructions.

Read MoreLMK Pipe Renewal has made the decision that personal safety takes precedent over company

property in all emergencies. No extreme action should be taken that Threatens personal safety.

Dial 911 in the event of an emergency.

Read MoreAll accidents involving injury or exposure to toxic chemicals must be reported to the Laboratory

Supervisor and the Lab Health and Safety Officer immediately. If an injury results from an

accident, an accident report form must be filled out by the personnel directly involved.

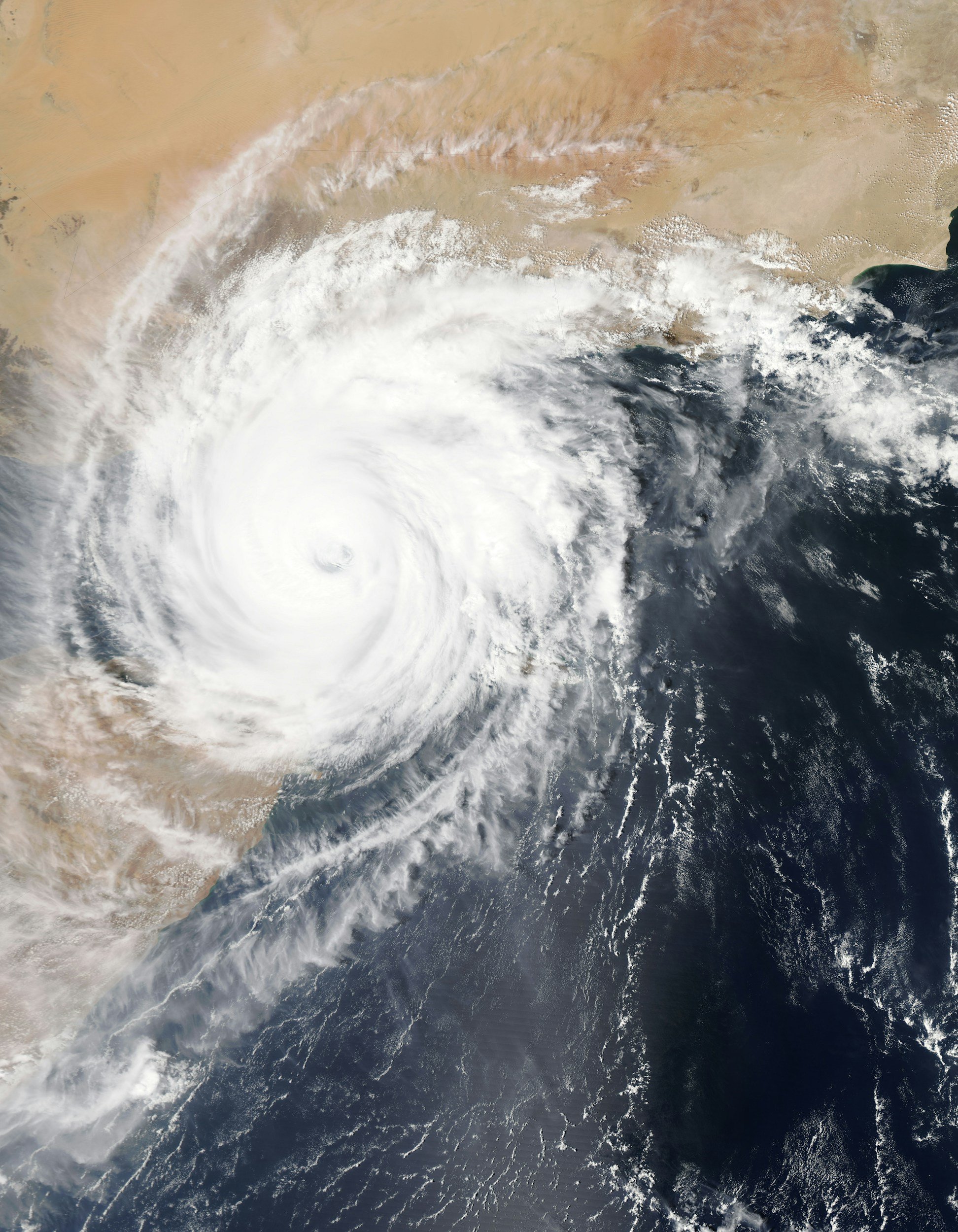

Read MoreIt is company policy to stop or delay construction activities, 24 to 48 hours prior to landfall

depending on the project’s geographical distance from our closest shop/yard. The only

exception would be for any activity related to prepping or securing the job site for the coming

storm.

Read MoreWeather plays a huge role in our ability to work safely when working outdoors. While rain, snow, ice, and hot temperatures are often discussed, less focus is given to the hazards wind can create for workers. It is important to realize the different hazards high winds can pose and what can be done to work safely in these conditions.

Read MoreThree-way communication can be critical in verifying a message is understood during a work task which can make all the difference in whether a worker is injured or not….

Read MoreNo matter if you or someone else is responsible for implementing a safeguard, safeguards should be verified that they are in place prior to beginning work….

Read MoreThere is an endless amount of acronyms when talking about safety. The acronym S.O.R.T. is a tool that can help remind us to take steps to address hazards and create a safe work environment. S.O.R.T stands for Stop, Observe, Recognize, and Take Ownership.

Read MoreThe hazards associated with electricity affect the majority of workplaces. Whether you are in general industry, construction, or even farming- electrical hazards are present. It is important to be able to recognize the electrical hazards around you and know how to mitigate them.

Read MoreSmoking is not permitted.

The consumption of food is not permitted in wetout area.

Beverages are allowed but may only be kept and consumed at "dry" personal desks or computer

stations. Drinking in any work isle or at "wet" benches is strictly prohibited. Beverages are

prohibited in the microbiology laboratory, dishwasher room, chemical storage area and near

fume hoods. Consumption of drinks is discouraged while an analyst is actively performing tests.

Read MoreKnow the safety rules and procedures that apply to the work that is being done. Determine the

potential hazards (e.g., physical, chemical, biological) and appropriate safety precautions before

beginning any new procedure.

Read More